Conversion Chart

Your Complete Fastener Conversion Chart & Guide

When you’re working on a project, whether it’s large-scale manufacturing or a small repair, choosing the right fastener size is critical. However, when fasteners come in both U.S. imperial and metric measurements, navigating between the two systems can quickly become confusing. At Fasteners Etc., Inc., we want to make your processes easier, so we’ve put together a handy fastener conversion chart for you to reference during your work.

This page is designed to make your work simpler, faster, and more accurate. With clear conversions between imperial fasteners and metric fasteners and expert tips from our knowledgeable team, you’ll always have the right information at your fingertips.

Simplify Your Fastener Projects with Accurate Conversions

Every project requires precision. Using the wrong fastener size can lead to material damage, compromised structural integrity, or wasted time. That’s why quick and reliable conversions matter.

Our fastener conversion chart eliminates the guesswork. It helps you:

- Translate between inch-based (imperial) and millimeter-based (metric) measurements

- Avoid costly mistakes by selecting the correct screw, bolt, or stud size

- Save time on the job site with accurate reference points

Whether you’re a contractor handling bulk orders, a maintenance professional sourcing replacement screws, a DIYer renovating or repairing, or a small business owner, this conversion table is your go-to resource for getting it right the first time.

Fastener Conversion Chart: Fraction, Inch, and Millimeter Table

Use this table to simplify the conversion process. Simply look at the size of the fastener you have, whether it’s in inches or millimeters, and find the corresponding fastener size in the other measurement system.

If you’re unsure of the fastener size, you may have to use digital calipers to get the diameter and length. These tools are handheld measuring instruments that use a digital encoder to display measurements on a screen, offering accurate and easy-to-read results.

| Fraction | Decimal | Millimeter | Fraction | Decimal | Millimeter | Fraction | Decimal | Millimeter | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/64 | 0.0156 | 0.3969 | 1 1/64 | 1.0156 | 25.7969 | 2 1/64 | 2.0156 | 51.1969 | ||

| 1/32 | 0.0313 | 0.7938 | 1 1/32 | 1.0313 | 26.1938 | 2 1/32 | 2.0313 | 51.5938 | ||

| 3/64 | 0.0469 | 1.1906 | 1 3/64 | 1.0469 | 26.5906 | 2 3/64 | 2.0469 | 51.9906 | ||

| 1/16 | 0.0625 | 1.5875 | 1 1/16 | 1.0625 | 26.9875 | 2 1/16 | 2.0625 | 52.3875 | ||

| 5/64 | 0.0781 | 1.9844 | 1 5/64 | 1.0781 | 27.3844 | 2 5/64 | 2.0781 | 52.7844 | ||

| 3/32 | 0.0938 | 2.3813 | 1 3/32 | 1.0938 | 27.7813 | 2 3/32 | 2.0938 | 53.1813 | ||

| 7/64 | 0.1094 | 2.7781 | 1 7/64 | 1.1094 | 28.1781 | 2 7/64 | 2.1094 | 53.5781 | ||

| 1/8 | 0.1250 | 3.1750 | 1 1/8 | 1.1250 | 28.5750 | 2 1/8 | 2.1250 | 53.9750 | ||

| 9/64 | 0.1406 | 3.5719 | 1 9/64 | 1.1406 | 28.9719 | 2 9/64 | 2.1406 | 54.3719 | ||

| 5/32 | 0.1563 | 3.9688 | 1 5/32 | 1.1563 | 29.3688 | 2 5/32 | 2.1563 | 54.7688 | ||

| 11/64 | 0.1719 | 4.3656 | 1 11/64 | 1.1719 | 29.7656 | 2 11/64 | 2.1719 | 55.1656 | ||

| 3/16 | 0.1875 | 4.7625 | 1 3/16 | 1.1875 | 30.1625 | 2 3/16 | 2.1875 | 55.5625 | ||

| 13/64 | 0.2031 | 5.1594 | 1 13/64 | 1.2031 | 30.5594 | 2 13/64 | 2.2031 | 55.9594 | ||

| 7/32 | 0.2188 | 5.5563 | 1 7/32 | 1.2188 | 30.9563 | 2 7/32 | 2.2188 | 56.3563 | ||

| 15/64 | 0.2344 | 5.9531 | 1 15/64 | 1.2344 | 31.3531 | 2 15/64 | 2.2344 | 56.7531 | ||

| 1/4 | 0.2500 | 6.3500 | 1 1/4 | 1.2500 | 31.7500 | 2 1/4 | 2.2500 | 57.1500 | ||

| 17/64 | 0.2656 | 6.7469 | 1 17/64 | 1.2656 | 32.1469 | 2 17/64 | 2.2656 | 57.5469 | ||

| 9/32 | 0.2813 | 7.1438 | 1 9/32 | 1.2813 | 32.5438 | 2 9/32 | 2.2813 | 57.9438 | ||

| 19/64 | 0.2969 | 7.5406 | 1 19/64 | 1.2969 | 32.9406 | 2 19/64 | 2.2969 | 58.3406 | ||

| 5/16 | 0.3125 | 7.9375 | 1 5/16 | 1.3125 | 33.3375 | 2 5/16 | 2.3125 | 58.7375 | ||

| 21/64 | 0.3281 | 8.3344 | 1 21/64 | 1.3281 | 33.7344 | 2 21/64 | 2.3281 | 59.1344 | ||

| 11/32 | 0.3438 | 8.7313 | 1 11/32 | 1.3438 | 34.1313 | 2 11/32 | 2.3438 | 59.5313 | ||

| 23/64 | 0.3594 | 9.1281 | 1 23/64 | 1.3594 | 34.5281 | 2 23/64 | 2.3594 | 59.9281 | ||

| 3/8 | 0.3750 | 9.5250 | 1 3/8 | 1.3750 | 34.9250 | 2 3/8 | 2.3750 | 60.3250 | ||

| 25/64 | 0.3906 | 9.9219 | 1 25/64 | 1.3906 | 35.3219 | 2 25/64 | 2.3906 | 60.7219 | ||

| 13/32 | 0.4063 | 10.3188 | 1 13/32 | 1.4063 | 35.7188 | 2 13/32 | 2.4063 | 61.1188 | ||

| 27/64 | 0.4219 | 10.7156 | 1 27/64 | 1.4219 | 36.1156 | 2 27/64 | 2.4219 | 61.5156 | ||

| 7/16 | 0.4375 | 11.1125 | 1 7/16 | 1.4375 | 36.5125 | 2 7/16 | 2.4375 | 61.9125 | ||

| 29/64 | 0.4531 | 11.5094 | 1 29/64 | 1.4531 | 36.9094 | 2 29/64 | 2.4531 | 62.3094 | ||

| 15/32 | 0.4688 | 11.9063 | 1 15/32 | 1.4688 | 37.3063 | 2 15/32 | 2.4688 | 62.7063 | ||

| 31/64 | 0.4844 | 12.3031 | 1 31/64 | 1.4844 | 37.7031 | 2 31/64 | 2.4844 | 63.1031 | ||

| 1/2 | 0.5000 | 12.7000 | 1 1/2 | 1.5000 | 38.1000 | 2 1/2 | 2.5000 | 63.5000 | ||

| 33/64 | 0.5156 | 13.0969 | 1 33/64 | 1.5156 | 38.4969 | 2 33/64 | 2.5156 | 63.8969 | ||

| 17/32 | 0.5313 | 13.4938 | 1 17/32 | 1.5313 | 38.8938 | 2 17/32 | 2.5313 | 64.2938 | ||

| 35/64 | 0.5469 | 13.8906 | 1 35/64 | 1.5469 | 39.2906 | 2 35/64 | 2.5469 | 64.6906 | ||

| 9/16 | 0.5625 | 14.2875 | 1 9/16 | 1.5625 | 39.6875 | 2 9/16 | 2.5625 | 65.0875 | ||

| 37/64 | 0.5781 | 14.6844 | 1 37/64 | 1.5781 | 40.0844 | 2 37/64 | 2.5781 | 65.4844 | ||

| 19/32 | 0.5938 | 15.0813 | 1 19/32 | 1.5938 | 40.4813 | 2 19/32 | 2.5938 | 65.8813 | ||

| 39/64 | 0.6094 | 15.4781 | 1 39/64 | 1.6094 | 40.8781 | 2 39/64 | 2.6094 | 66.2781 | ||

| 5/8 | 0.6250 | 15.8750 | 1 5/8 | 1.6250 | 41.2750 | 2 5/8 | 2.6250 | 66.6750 | ||

| 41/64 | 0.6406 | 16.2719 | 1 41/64 | 1.6406 | 41.6719 | 2 41/64 | 2.6406 | 67.0719 | ||

| 21/32 | 0.6563 | 16.6688 | 1 21/32 | 1.6563 | 42.0688 | 2 21/32 | 2.6563 | 67.4688 | ||

| 43/64 | 0.6719 | 17.0656 | 1 43/64 | 1.6719 | 42.4656 | 2 43/64 | 2.6719 | 67.8656 | ||

| 11/16 | 0.6875 | 17.4625 | 1 11/16 | 1.6875 | 42.8625 | 2 11/16 | 2.6875 | 68.2625 | ||

| 45/64 | 0.7031 | 17.8594 | 1 45/64 | 1.7031 | 43.2594 | 2 45/64 | 2.7031 | 68.6594 | ||

| 23/32 | 0.7188 | 18.2563 | 1 23/32 | 1.7188 | 43.6563 | 2 23/32 | 2.7188 | 69.0563 | ||

| 47/64 | 0.7344 | 18.6531 | 1 47/64 | 1.7344 | 44.0531 | 2 47/64 | 2.7344 | 69.4531 | ||

| 3/4 | 0.7500 | 19.0500 | 1 3/4 | 1.7500 | 44.4500 | 2 3/4 | 2.7500 | 69.8500 | ||

| 49/64 | 0.7656 | 19.4469 | 1 49/64 | 1.7656 | 44.8469 | 2 49/64 | 2.7656 | 70.2469 | ||

| 25/32 | 0.7813 | 19.8438 | 1 25/32 | 1.7813 | 45.2438 | 2 25/32 | 2.7813 | 70.6438 | ||

| 51/64 | 0.7969 | 20.2406 | 1 51/64 | 1.7969 | 45.6406 | 2 51/64 | 2.7969 | 71.0406 | ||

| 13/16 | 0.8125 | 20.6375 | 1 13/16 | 1.8125 | 46.0375 | 2 13/16 | 2.8125 | 71.4375 | ||

| 53/64 | 0.8281 | 21.0344 | 1 53/64 | 1.8281 | 46.4344 | 2 53/64 | 2.8281 | 71.8344 | ||

| 27/32 | 0.8438 | 21.4313 | 1 27/32 | 1.8438 | 46.8313 | 2 27/32 | 2.8438 | 72.2313 | ||

| 55/64 | 0.8594 | 21.8281 | 1 55/64 | 1.8594 | 47.2281 | 2 55/64 | 2.8594 | 72.6281 | ||

| 7/8 | 0.8750 | 22.2250 | 1 7/8 | 1.8750 | 47.6250 | 2 7/8 | 2.8750 | 73.0250 | ||

| 57/64 | 0.8906 | 22.6219 | 1 57/64 | 1.8906 | 48.0219 | 2 57/64 | 2.8906 | 73.4219 | ||

| 29/32 | 0.9063 | 23.0188 | 1 29/32 | 1.9063 | 48.4188 | 2 29/32 | 2.9063 | 73.8188 | ||

| 59/64 | 0.9219 | 23.4156 | 1 59/64 | 1.9219 | 48.8156 | 2 59/64 | 2.9219 | 74.2156 | ||

| 15/16 | 0.9375 | 23.8125 | 1 15/16 | 1.9375 | 49.2125 | 2 15/16 | 2.9375 | 74.6125 | ||

| 61/64 | 0.9531 | 24.2094 | 1 61/64 | 1.9531 | 49.6094 | 2 61/64 | 2.9531 | 75.0094 | ||

| 31/32 | 0.9688 | 24.6063 | 1 31/32 | 1.9688 | 50.0063 | 2 31/32 | 2.9688 | 75.4063 | ||

| 63/64 | 0.9844 | 25.0031 | 1 63/64 | 1.9844 | 50.4031 | 2 63/64 | 2.9844 | 75.8031 | ||

| 1 | 1.0000 | 25.4000 | 2 | 2.0000 | 50.8000 | 3 | 3.0000 | 76.2000 |

This chart can be used by workers in various industries, including automotive, manufacturing, aerospace, and more. It’s also helpful if you’re doing a DIY project and have fasteners of different systems that you aren’t sure how to convert.

Understanding Fastener Measurement Systems

Nothing screws up your productivity and motivation faster than realizing you used the wrong size fastener. Avoid this mistake by clearly understanding the difference between the two commonly used systems and their measurements.

U.S. Imperial vs. Metric: Decoding Fastener Sizes

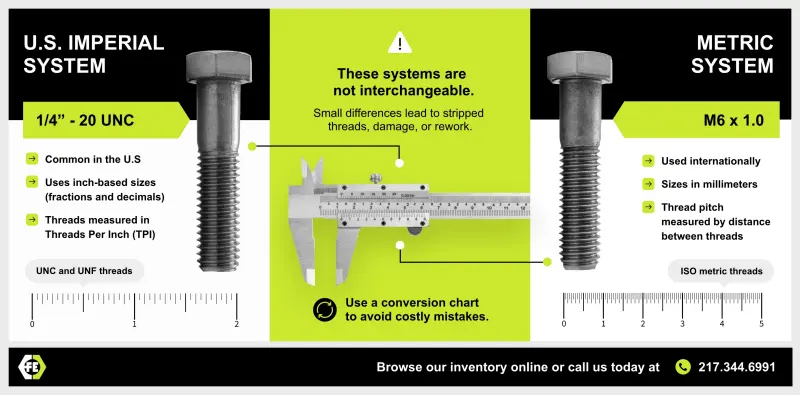

Fasteners are measured using two primary systems: U.S. imperial and metric. Understanding how they differ is the first step to ensuring accuracy in your projects.

The imperial system is common in the United States. It uses non-decimal-based units like inches, fractions, and gauge numbers to define screw sizes. Threading often follows Unified National Coarse (UNC) and United National Fine (UNF) standards to define threads per inch.

The metric system is used internationally and is the global standard for measurement. However, it is increasingly being used by U.S. industries that have global suppliers. The metric system is decimal-based and uses prefixes like kilo and milli to denote powers of ten. In this system, measurements are given in millimeters (mm) for both diameter and length, and the thread pitch is explicitly defined by the distance between threads.

While these systems differ, both are widely used across industries. That’s why conversion tools are so valuable. They allow you to easily cross-reference fastener sizes between the two systems, ensuring a perfect fit. However, because of the different governing bodies, there may be some variance. These bodies include:

- American National Standards Institute (ANSI)

- ASTM International

- Industrial Fasteners Institute (IFI)

- SAE International

- International Organization for Standardization (ISO)

Our conversion chart provides the inch equivalent and metric conversion you need for screws, bolts, studs, and more. This makes it quick and easy to determine which you should be using, helping to prevent mistakes and make your process smoother.

Frequently Asked Questions About Fastener Conversion

You may have questions about fasteners and their sizing. We’ve answered some common queries about them to give you more insight.

Your Questions About Fastener Sizing Answered

Why are there different fastener size standards (imperial vs. metric)?

There are different fastener size standards because different regions developed their own measurement system. The U.S. has historically used the imperial system, while much of the world has adopted metric. However, globalization means that global manufacturers often work with both.

That's why our fastener conversion chart is essential. It bridges the gap between the two distinct systems and ensures fastener compatibility. Standards like ANSI for imperial and ISO for metric guide these measurements.

How do I measure fastener size accurately for conversion?

Use digital calipers for the most precise measurement of both diameter and length. Once you have those numbers, our conversion chart helps you easily find the corresponding size in either inches or millimeters.

What do the numbers on screws (e.g., #6, #8) mean in the conversion chart?

The numbers on screws indicate the diameter of the screw in the imperial system. For example, a #8 screw has a diameter of approximately 0.164 inches, or 5/32 of an inch. This screw is thicker than a #6 screw and thinner than a #10.

This number is part of the gauge system. Higher numbers correlate with larger diameters. However, the relationship between numbers isn't simply linear. Our size chart makes it easy to see the exact equivalent in both systems.

Can this fastener conversion chart be used for bolts, studs, and other threaded fasteners?

Yes, this fastener conversion chart can be used for bolts, studs, machine screws, threaded rods, and other fasteners, such as:

- Socket head cap screws and socket set screws

- Hex bolts and hex cap screws

- Pan head screws and bolts

- Locknuts and lock washers

- Rivets

- Nylon insert nuts

This universality is possible because all these fasteners follow similar sizing conventions. However, you should always double-check application requirements, but this chart can be used as a baseline reference.

Why is matching fastener size with pilot hole size crucial?

When completing a construction project, matching the fastener size to the pilot hole is essential. This is because if your fastener doesn't match the correct pilot hole size, you risk splitting material, stripping threads, or weakening the connection. The conversion chart helps you determine the right decimal or millimeter measurement for drilling, which can help ensure a secure fit.

What is a thread pitch?

A thread pitch is the distance between the crests of two adjacent threads. In the metric system, it is measured in millimeters. Likewise, it is measured as threads per inch (TPI) for imperial screws. A coarse thread screw has a larger pitch and is easier to assemble. A fine thread screw has a smaller pitch that offers high precision and minimizes self-loosening.

How do you use digital calipers to measure the size of a fastener?

To measure a fastener's size with digital calipers, there are a few steps to follow. They include:

- Calibrating the calipers: Close the jaws of the calipers until they meet, then press the "zero" button to be sure the scale reads zero.

- Opening the jaws: Slide the moving jaw to open the large outside jaws of the caliper.

- Placing the jaws around the fastener: Place the outside jaws around the diameter of the fastener, ensuring they are parallel to the surface.

- Tightening gently: Close the jaws slowly and gently until they make firm contact with the fastener. Don't over-tighten them to avoid damaging the caliper or getting an inaccurate measurement.

- Reading the display: Look at the digital screen to see the measured diameter of the fastener.

- Measuring the length: To measure the fastener's length, place the caliper's underside from the head of the bolt to the end of the threaded section. Repeat the above steps to get the measurement.

Need a Specific Fastener Size? Request a Quote for Bulk Orders

Whenever you’re working on a project, having the right fastener size is vital. Make sure you can correctly convert imperial screws or bolts to metric and back with our conversion chart.

However, sometimes even with the best conversion tools, you’ll find you don’t have a good equivalent in stock. If you need a fastener that’s harder to find or need it in large quantities, Fasteners Etc., Inc. can help. We work with both large-scale industrial clients and small businesses, tailoring solutions to fit your needs. Whether you’re sourcing thousands of bolts for production or just a handful of specialty screws, our team is here to help. We’ll make sure you get the right solution for your project, delivered with the personal service you expect from us.