Fastener Guide: Comparing Common Types, Materials, and Uses

Choosing the right fastener can make or break a project. From construction sites to factory floors to DIY workshops, fasteners hold everything together. This guide is designed to help you make confident choices by directly comparing the most common types of fasteners based on their material, application, and head or drive styles.

Selecting the right fastener does more than get parts to fit together. It also ensures the performance, safety, and ease of installation of your project. The right choice can prevent material damage, reduce maintenance needs, and improve overall product quality and reliability.

If you’re looking for a deeper understanding of how to select the ideal fastener for your project, we recommend checking out our companion guide on general selection factors when choosing a fastener. This article builds upon that foundation by offering side-by-side comparisons of common fasteners. It gives you the quick technical contrasts and fastener basics you need for accurate product specification.

Bolt Types Compared

Bolts are among the most widely used fasteners in industrial and construction applications. They’re designed to deliver high tensile strength and secure connections between metal, wood, and composite materials. Below, we compare several common bolt types and their unique characteristics.

Hex Bolts vs. Carriage Bolts

Hex bolts are standard in metal construction, machinery, and structural assemblies, offering high torque and easy removal. They feature a six-sided head for wrench tightening. Additionally, their ease of removal makes them ideal for adjustable assemblies.

Conversely, carriage bolts are primarily used in wood applications, where the smooth domed head creates a clean, finished appearance and prevents pull-through. Carriage bolts have a rounded head with a square neck that locks into wood or studs, preventing rotation during tightening. They offer greater tamper resistance, as the head provides no drive recess.

Flange Bolts vs. Hex Bolts

Flange bolts have a built-in washer that spreads the load, reducing assembly time and protecting surfaces. They provide a wider bearing surface, which helps distribute pressure evenly and reduces the likelihood of surface damage. Flange bolts are common in automotive and assembly line environments for faster, one-step installation.

Conversely, hex bolts require a separate washer, adding flexibility but increasing component count. They are commonly used across general construction and equipment repair.

Heavy Bolts vs. Structural Bolts

Heavy hex bolts are a common type of structural bolt. They feature a larger and wider head for greater clamping force. Typical grades include A307 for general use and A325 or A490 for high-strength structural work.

Structural bolts are a broad category that encompasses various ASTM-specific high-strength fasteners for demanding infrastructure projects. They often require tensioning methods such as Direct Tension Indicator (DTI) washers or turn-of-nut techniques, ensuring precise load control.

Heavy bolts and structural bolts often have the following applications:

- Heavy hex bolts: These are used in non-critical heavy-duty applications like heavy equipment assembly.

- Structural bolts: These are designed for critical steel-to-steel connections in bridges, high-rises, and infrastructure.

Nut Types Compared

Nuts pair with bolts to complete a secure fastening system. Choosing the right nut type ensures proper fit, vibration resistance, and long-term reliability.

Hex Nuts vs. Lock Nuts

Hex nuts are the industry standard for general applications and are available in a range of strength grades. They are easily reusable when the threads are intact.

Lock nuts are made for high-vibration environments, such as engines or heavy machinery, where maintaining torque is critical. They may use nylon inserts, distorted threads, knurled designs, or metal crimping to resist loosening under vibration. Unlike hex nuts, they are often a single-use fastener due to the deformation or wear on the locking feature.

Screw Types Compared

Screws are among the most versatile fasteners, used across virtually every industry. Their self-threading design makes them ideal for direct installation into wood, metal, or plastic.

Self-Tapping Screws vs. Tek Screws (Self-Drilling)

Self-tapping screws require a pre-drilled pilot hole to cut internal threads. Conversely, Tek self-drilling screws feature a built-in drill tip, eliminating the need for pre-drilling and saving you time.

Both self-tapping and self-drilling screws are used in sheet metal, HVAC systems, and light construction. However, they have some differences:

- Self-tappers are common for wood and fiberglass.

- Self-drillers are preferred for steel-to-steel connections or metal-to-wood connections.

Both types of screws are available in zinc-plated steel for general indoor use. You can also buy stainless steel threaded fasteners for outdoor and corrosion-prone environments.

Hex Cap Screws vs. Socket Cap Screws

Hex cap screws use an external wrenching hex head for high-torque applications. They are commonly used in machinery, construction, and agricultural equipment.

Socket cap screws use an internal hex drive, or Allen key, making them ideal for tight spaces. They are used for precision assemblies, robotics, and tooling where aesthetics or clearance are key.

Lag Screws vs. Wood Screws

Lag screws are thicker and longer, used for heavy-duty wood construction like decks and timber framing. They have a thick shank for superior strength and load-bearing capacity, coarse threads for excellent wood grip, and a hexagonal head that needs a wrench or ratchet for high-torque installation. They require pre-drilled pilot holes and a clearance hole for the shaft before driving.

Wood screws are smaller and better suited for cabinetry, furniture, or light framing. They come in a range of lengths and gauges to suit different applications. They have finer threads than lag screws to create a secure hold. Additionally, they have various heads, including Phillips or slotted, so you can use common screwdrivers and pre-drilled holes.

Fastener Materials and Finishes

Selecting the right material is essential for achieving the proper balance between strength, corrosion resistance, and cost.

Popular materials include:

- Stainless steel: This material offers excellent corrosion resistance and moderate strength. It is ideal for outdoor, marine, or food-grade environments.

- Zinc-plated steel: This is the most common, cost-effective finish. It is good for indoor use with limited moisture exposure.

- Hot-dip galvanized steel: This thick, rugged coating offers superior corrosion resistance for outdoor or agricultural applications.

- Brass: This non-magnetic decorative finish is commonly used in electrical, plumbing, and aesthetic installations.

- Titanium: This lightweight material is exceptionally strong. It is ideal for aerospace, high-performance, or corrosive industrial settings.

Not all steel is equal. Always verify the grade and tensile strength before specifying a fastener, especially in critical load-bearing assemblies.

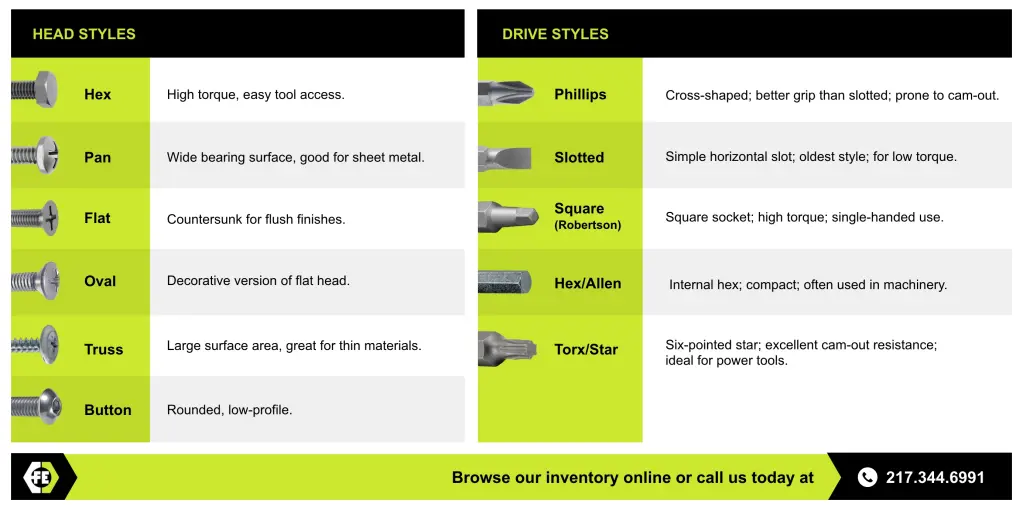

Head and Drive Styles

The head and drive of a fastener affect not just appearance, but also torque, accessibility, and tool compatibility.

Heads

The most common head styles include:

- Hex: These have high torque and tool accessibility.

- Pan head: These have a wide bearing surface for sheet metal.

- Flat: These are countersunk for flush finishes.

- Oval heads: These are a decorative variation of flat heads.

- Truss heads: These have a large surface area, ideal for thin materials.

- Button heads: These have a rounded appearance for low-profile applications.

Use countersunk heads when you need a flush surface and non-countersunk heads when surface bearing is more important.

Drives

There are a variety of drive types, including:

- Phillips: This is common and easy to align. Its cross-shaped slot offers better grip than slotted, but it’s prone to cam-out at high torques.

- Slotted: This is simple with a single, horizontal slot. It’s the oldest and prone to cam-out, making it great for low-torque use.

- Square (Robertson): This has a square-shaped socket. It’s good for high torque applications and single-handed installation.

- Hex/Allen: This is compact and precise with an internal hexagonal socket. It is often used in machinery because it’s capable of high torque.

- Torx/Star: This has an excellent grip powered by a six-pointed star-shaped recess. It is ideal for power tools and assembly lines because it offers excellent resistance to cam-out.

For DIY or general maintenance, Phillips and square drives are most accessible. For industrial assembly, Torx and hex drives provide superior control and efficiency.

Threads and Sizing

Understanding thread type and size is key to ensuring compatibility and performance.

- Coarse threads: These are faster to install, more resistant to cross-threading, and better for soft materials. They have wide, deep ridges spaced further apart.

- Fine threads: These are stronger in tension and vibration-resistant but require more precise alignment. They have narrow, shallow ridges spaced closer together.

When measuring threads, there are two types to keep in mind. Threads per inch (TPI) applies to standard inch fasteners, while thread pitch (mm) applies to metric fasteners. Matching the correct thread type to the material prevents stripping and ensures full engagement and a secure connection.

Quick Tips:

To choose the right screw thread, match coarse threads with softer materials, such as wood and plastic, and fine threads with harder materials. Coarse threads are great for quick assembly, while fine threads are ideal for precise tightening.

- Machine screws: These match threads to tapped holes or nuts.

- Wood screws: These use coarse threads for gripping fiber materials.

- Sheet metal screws: These use sharp threads for cutting into thin material.

Need Fastener Advice? Request a Quote or Contact Us

The right fastener holds components together and improves strength, durability, safety, and installation efficiency. Whether you’re sourcing for a university lab, an MRO department, or a large-scale manufacturing project, Fasteners Etc., Inc. can help.

Our veteran-owned team takes pride in offering personalized, expert service to every customer. From sourcing specialty hardware to providing application-specific recommendations, we’re here to ensure you get the right fastener, every time.

Need help choosing the right fastener for your next project? Contact us today or request a quote for fast, accurate, and reliable assistance.