Tough Fasteners Guide

Fasteners: Understanding Grades, Materials, and Applications

In industries where safety, performance, and reliability are non-negotiable, high-strength fasteners play a critical role. These specialized bolts, screws, and nuts are the silent workhorses that hold together everything from cars and airplanes to heavy machinery and infrastructure. Without them, modern construction, manufacturing, and engineering wouldn’t be possible.

Choosing the right fastener requires more than just picking the right size hex cap bolt or hex cap screw. It also involves choosing a fastener that can withstand stress and bear loads, resist corrosion, and maintain its stability over time. For projects that demand long-lasting performance, high-strength fasteners are the standard choice.

At Fasteners Etc., Inc., we understand how important it is to select the right fastener for the job. With decades of experience, personalized customer service, and the reliability of a veteran-owned business, we’re here to guide you and help you understand the ins and outs of high-strength fasteners.

What Are High-Strength Fasteners?

High-strength fasteners are engineered hardware designed to deliver superior performance under heavy loads, high stress, or extreme environmental conditions. Unlike standard fasteners, which are intended for light-duty projects, high-strength fasteners are manufactured to meet strict standards for tensile strength, yield strength, and mechanical properties.

- Tensile strength: This measures how much force a fastener can withstand being stretched or pulled before breaking.

- Yield strength: This refers to the point where the fastener begins to permanently deform under pressure.

- Mechanical properties: These include hardness, ductility, and fatigue resistance, which determine how well the fastener performs in the real world.

These properties make high-strength fasteners essential in applications where failure and a poor connection aren’t an option, such as in bridges, automotive engines, aerospace components, or industrial machines that run nonstop.

Fastener Grades and Standards

When selecting fasteners, grades and standards help ensure quality and consistency. Manufacturers follow strict guidelines from organizations such as the American Society of Testing and Materials (ASTM) or ASTM International, the International Organization for Standardization (ISO), and the Society of Automotive Engineers (SAE).

These standards define how a fastener should be manufactured, tested, and rated. They also provide benchmarks for mechanical performance, making it easier to compare fasteners across different suppliers.

For reference, the most common fastener grades include:

- Grade 2: This is a low- or medium-strength option, typically made of low-carbon steel. They are best for general-purpose, non-critical applications.

- Grade 5: This is stronger than Grade 2 and often heat-treated. They are commonly used in automotive applications for parts that need moderate strength.

- Grade 8: This is high-strength, heat-treated, and ideal for heavy-duty applications where safety and performance are top priorities.

The grade indicates the strength and material properties of the fastener and gives you an approximation of how much load it can handle before failure. The higher the grade, the stronger the fastener.

Fastener strength is usually expressed in pounds per square inch (psi) or megapascals (MPa). A Grade 2 fastener typically has a tensile strength of 60,000 psi or 414 MPa. Likewise, a Grade 5 fastener has a tensile strength of 120,000 psi (830 MPa), while a Grade 8 fastener has a 150,000-psi tensile strength (1,035 MPa).

This consistency across standards gives engineers and builders confidence that the fasteners they select will perform as expected.

Materials Used in Fasteners

What a fastener is made of impacts the strength, corrosion resistance, and overall stability of a specific application. Different industries and environments call for various materials to ensure a stable and secure connection over time.

Typically, high-strength fasteners use the following materials:

- Alloy steel: This offers a combination of strength and toughness, making it a go-to choice for heavy-duty applications like construction machinery and automotive components.

- Stainless steel: Known for excellent corrosion resistance, stainless steel fasteners are ideal for outdoor projects, marine applications, and industries where exposure to moisture is unavoidable.

- Carbon steel: A cost-effective and widely used material, carbon steel fasteners are versatile and suitable for many general construction and manufacturing needs.

- Titanium: Lightweight yet strong, titanium fasteners are essential in aerospace, defense, and other industries where both high strength and weight reduction are critical.

At Fasteners Etc., Inc., we provide a full range of fasteners in various materials, so you can find exactly what you need. Whether it’s a corrosion-resistant option for outdoor use or ultra-high-strength bolts for mission-critical equipment, you’ll find it in stock.

Understanding Fastener Sizes and Threading

When it comes to fasteners, size and threading are just as important as material and grade. The dimensions of a bolt determine not only how it fits, but also how well it holds under a load.

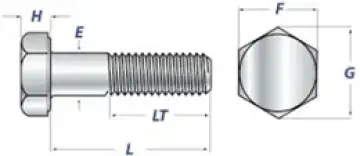

Bolts use the following dimensions:

- Diameter (E): This refers to the thickness of the bolt shaft. Larger diameters typically mean a higher load capacity.

- Length (L): This is the distance from the bolt head to the end of the threads. Correct length ensures a proper connection and load distribution.

- Head height (H): A taller head allows for better engagement, which means more torque can be applied. It also improves shearing resistance.

- Head width (F & G): The size of the bolt’s head affects how the force is distributed. The larger the width, the more force is distributed.

Threading is also critical. The thread of a bolt is the spiral ridge going around the shaft that is inserted into the base material. A coarse thread or pitch has a deeper ridge and has wider spaces, making it ideal for soft materials like wood. Coarse threads are usually easier to assemble and resist cross-threading.

Conversely, a fine thread or pitch has shallow ridges that are close together, making it ideal for hard materials with precise fits. They offer greater strength and better vibration resistance.

| DIAMETER | COARSE THREAD (UNC) | FINE THREAD (UNF) |

|---|---|---|

| 1/4" | 1/4"-20 | 1/4"-28 |

| 3/8" | 3/8"-16 | 3/8"-24 |

| 1/2" | 1/2"-13 | 1/2"-20 |

| 5/8" | 5/8"-11 | 5/8"-18 |

| 3/4" | 3/4"-10 | 3/4"-16 |

| 7/8" | 7/8"-9 | 7/8"-14 |

| 1" | 1"-8 | 1"-12 |

Plating and Coating for Fasteners

Even the strongest fastener can fail prematurely if exposed to the wrong environment. That’s why plating and coatings are essential. They help extend the life of high-strength fasteners and add extra protection from the elements.

Common coating options include:

- Zinc clear: A thin layer of zinc is applied via electroplating, followed by a clear chromate coating for a shiny finish. This coating offers limited corrosion resistance and is common for Grade 2 and 5 fasteners in indoor or dry environments.

- Zinc yellow: A thin layer of zinc is applied with electroplating, followed by a yellow chromate coating for a golden finish. It offers improved corrosion resistance suitable for light moisture.

- Mechanically galvanized: This is a cold bonding of zinc on heavy-duty parts. It produces a uniform finish, offers excellent corrosion resistance, and is great for general-purpose outdoor use.

- Hot dip galvanized: Fasteners are dipped into hot zinc, resulting in a thick, durable coating. It is ideal for outdoor and marine environments where exposure to moisture and salt is constant.

Applications of High-Strength Fasteners

High-strength fasteners are essential across a wide range of industries. No matter what you use them for, the goal of a high-strength fastener is to create stable connections that won’t fail under stress and pressure.

High-strength fasteners are commonly used in the following applications:

- Automotive: They are used in engines, suspensions, and chassis, where vibration and high stress are constant

- Heavy machinery: These fasteners are essential in mining, construction, and agricultural equipment, where fasteners must hold up under extreme loads and continuous use.

- Structural construction: They are found in bridges, high-rise buildings, and large-scale infrastructure projects, where the integrity of fasteners ensures public safety.

- Industrial machinery and manufacturing: These fasteners are used in equipment assembly, production lines, and other environments that demand precision and consistency.

- Aerospace: Though not always visible, aerospace fasteners are engineered to withstand extreme temperatures, pressure changes, and vibration, where even the smallest failure can have major consequences and costly repairs.

How to Choose the Right Fastener

With so many grades, materials, and coatings available, how do you choose the right one? It comes down to evaluating several key factors:

- Material: Match the fastener’s strength and resistance to the environment where it will be used.

- Grade: Ensure the grade meets the necessary standards for strength and reliability.

- Size and threading: Select dimensions that ensure proper fit and performance.

- Coating: Be sure the coating will protect against corrosion and environmental wear.

- Application-specific needs: Consider temperature, vibration, and exposure to chemicals or moisture.

At Fasteners Etc., Inc., we take the guesswork out of comparing and choosing fasteners. Our team works directly with customers to help them identify the right product for their specific needs, whether it’s a single small project or a large-scale industrial order.

Why Choosing the Right High-Strength Fastener Matters

A project’s success depends on the smallest details, and high-strength fasteners are no exception. Using the wrong fastener or one that isn’t strong enough for the job can lead to delays, costly repairs, or even safety risks.

Choosing the right fastener means choosing durability, safety, and long-term performance. Material, coating, grade, and proper size all play a role in ensuring connections remain secure over time.

At Fasteners Etc., Inc., we take pride in being a trusted, veteran-owned supplier that combines deep industry knowledge with a commitment to personalized service. Whether you’re managing a major construction project, maintaining heavy machinery, or sourcing specialized construction fasteners, we’re here to provide reliable solutions tailored to your needs.

We offer a wide selection of quality products and high-strength fasteners made from high-quality materials. Our assortment includes everything from Grade 8 bolts to hot-dip galvanized anchor bolts, lock nuts, and flat washers. More importantly, we provide guidance and support to help you make the right choice.

Need help selecting the perfect fastener for your project? Contact us today for expert advice or to request a quote.